3D Printing, Inkjet

3d printing

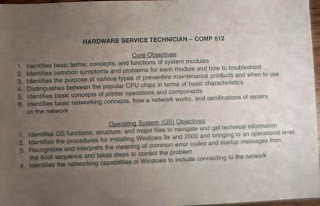

Yeas ago, while sitting around the table with some very talented phd's, technicians and engineers in Cambridge I could see the 3 dimensional technology would have some practical applications. Discussing the subject I became aware that there was already work underway with those with lineages from the likes of Domino sciences and other groundbreaking entities from previous generations. I could see it would be an interest to corporations and even military work both in the field and in the lab and carry with it an innovative approach in building and creating solutions. There are a few different methods including jetting through the nozzles, building layers upon each other as well as a method that builds up layers after the print swath leaves layers of specially formulated ink on top of specially formulated powder's after curing each layer.

3d objects can be printed after software takes a CAD image and slices the files into thin layers (unique slices) with instructions for the printer. There are free open source software packages like MeshLab that do a great job at this as well as other options free and at cost from AutoDesk etc.

At times in development there can be some interesting finds when attempting different prints and images may be re-sliced a few times by talented engineeers in order to get the desired result.

A few companies offer desktop models with user friendly software packages that can be used out of the box for simple object creation by the end user. The cost is becoming more realistic for consumers as progress is made.

It seems there is still allot of wonder as to how to use this technology.

There are 3d scanning devices and companies springing up around the scanning end as well as some handheld wand type scanners created by some of the printer companies that scan an object and process the information to the slicing software. Some of the scanning technology I have seen can be tedious at the moment requiring placing a series of numerous tiny white stickers on an object while a scanner that consists of 2 cameras and a laser at the center captures images as the object is rotated by the user to various points.

Contrary to some of the current beliefs I have seen materials made that have good strength and even some processes that have a high degree of speed.

Some of the 3d technology I have seen is impressive

I have been out of the Inkjet PIJ and TIJ technology field for so long it was quite and interest to see the technology again as I have briefly been back into a few companies for acquirements in the technology before entering back into the aerospace industry. I will be writing some key notes about the technology soon and posting them.

Yeas ago, while sitting around the table with some very talented phd's, technicians and engineers in Cambridge I could see the 3 dimensional technology would have some practical applications. Discussing the subject I became aware that there was already work underway with those with lineages from the likes of Domino sciences and other groundbreaking entities from previous generations. I could see it would be an interest to corporations and even military work both in the field and in the lab and carry with it an innovative approach in building and creating solutions. There are a few different methods including jetting through the nozzles, building layers upon each other as well as a method that builds up layers after the print swath leaves layers of specially formulated ink on top of specially formulated powder's after curing each layer.

3d objects can be printed after software takes a CAD image and slices the files into thin layers (unique slices) with instructions for the printer. There are free open source software packages like MeshLab that do a great job at this as well as other options free and at cost from AutoDesk etc.

At times in development there can be some interesting finds when attempting different prints and images may be re-sliced a few times by talented engineeers in order to get the desired result.

A few companies offer desktop models with user friendly software packages that can be used out of the box for simple object creation by the end user. The cost is becoming more realistic for consumers as progress is made.

It seems there is still allot of wonder as to how to use this technology.

There are 3d scanning devices and companies springing up around the scanning end as well as some handheld wand type scanners created by some of the printer companies that scan an object and process the information to the slicing software. Some of the scanning technology I have seen can be tedious at the moment requiring placing a series of numerous tiny white stickers on an object while a scanner that consists of 2 cameras and a laser at the center captures images as the object is rotated by the user to various points.

Contrary to some of the current beliefs I have seen materials made that have good strength and even some processes that have a high degree of speed.

Some of the 3d technology I have seen is impressive

I have been out of the Inkjet PIJ and TIJ technology field for so long it was quite and interest to see the technology again as I have briefly been back into a few companies for acquirements in the technology before entering back into the aerospace industry. I will be writing some key notes about the technology soon and posting them.

.png)